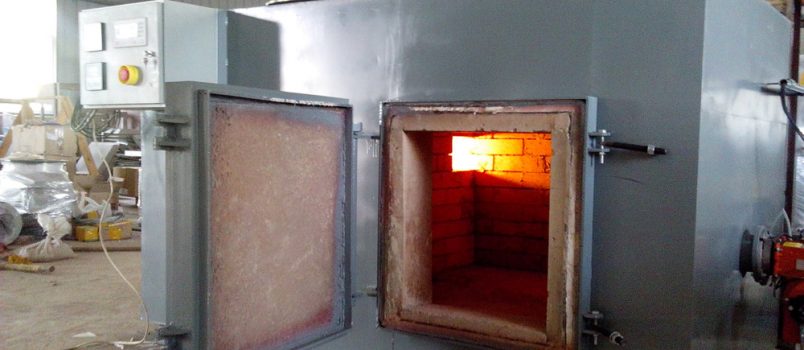

Incineration of biomedical waste

– intended to destroy and without polluting the environment, biomedical anatomical solidand non-anatomical waste‑ Smoke burning incinerator with a total volume of combustion chamber of approximately1 m3 (± 10%), with manual waste loading via a front door with an inspection flap (to check the flame) eliminatory‑ First combustion Chamber: more than 60% of the total volume‑ Post combustion Chamber (burning of smoke): Up to 40% of the total volume‑ Interior lining of chambers made of refractory material (nature to be indicated) making itpossible to reach and maintain a temperature up to 1000 °C eliminatory– Forced air Convection (by motorised Fan kW maximum) eliminatory– automatic cycle of maintaining the working temperature (burner control)– Insulating Layer (nature of the materials to indicate) between the combustion chamberand the exterior metal structure, including loading door (less than 60 °C on the frame in anormal regime), heat resistant layers of external protection – Calorific power required: 115 to 150 kW (418,000 to 543 400 kJh-1)– automatic illumination burners (electrical or piezoelectric) with security of flamepresence eliminatory– heating oil supply (diesel): 8 litres/hour maximum– Fuel Injection pump for 1 kW maximum– autonomy Tank of approx. 150 litres fitted with a booster pump– An expansion chamber provided with an ambient air intake flap located in the flue/burntgases path reduces the gas ejection velocity and dilutes it– The discharge into the atmosphere should be free of the following (results certified by amonitoring body acceptable by the purchaser): carbon monoxide (CO <0.1%), nitrogen oxides (Nox) and carbon (<8%), unburned fuel and hydrocarbons (<0.3 ‰), solidparticles (<7%).– Front or side control box comprising: * on switch * Getting started * Emergency stop * Choice of cycle (manual or automatic) * Choice of working temperature * Choice of cycle time * Ventilation * Priming of burners* Operation and phase indication indicators (presence of flame, temperature, time, fan, endof cycle, fault alarms, on / off, …)Safety devices :– Flame presence security: stop and alarm after several unsuccessful attempts to sparkEliminatory– overheating safety: fuel cutoff in the event of excess temperature Eliminatory– Security all closed doors (except possible inspection door)– Fuse protection– Disconnector to completely isolate the device during maintenance. Spare parts to provide:– 01 door seal– 01 set all of the light indicators– 01 set of all thermocouples– 02 sets of the nozzles of the burners– 01 set of ignition systems of the flames– 01 set of coils of all switches– 01 set of coils of all solenoid valves– 01 replacement kit for the fuel injection pump – 02 sets of all protection fusesEach equipment will be supplied with:– the local – 01 fireplace – 01 ash tray with a displacement scraper– 01 kit for cleaning the nozzles of the burners– 01 adapted manual igniter (in case of automatic ignition failure)– Electrical box for mains connection with at least one modular circuit breaker of suitablesize– 02 powder fire extinguishers (with their wall hangers)– 01 maintenance kit-1 UPS of adequate power-1 voltage stabilizer with recovery time – All the other accessories necessary for the proper functioning of the equipment– 01 user and maintenance manual in French